Back to Blog

Smart Manufacturing

Smart Factory Implementation for SMEs: Starting Small, Thinking Big

Karan SharmaJuly 30, 20259 min

A practical guide to implementing smart factory technologies in small and medium enterprises, focusing on scalable solutions and clear ROI.

# Let's Be Honest About Smart Factories

Most "smart factory" articles show pristine German or Japanese facilities with robots everywhere, AR headsets, and AI doing everything.

Then you look at your factory and think, "That's impossible for us."

But here's what I've learned: Smart factories aren't built overnight. They're built sensor by sensor, system by system, improvement by improvement.

Last year, we helped a 150-employee precision machining shop in Coimbatore implement their first smart factory technologies. Total investment? ₹12 lakhs. Payback? 7 months.

No robots. No AR. Just smart, practical digital solutions.

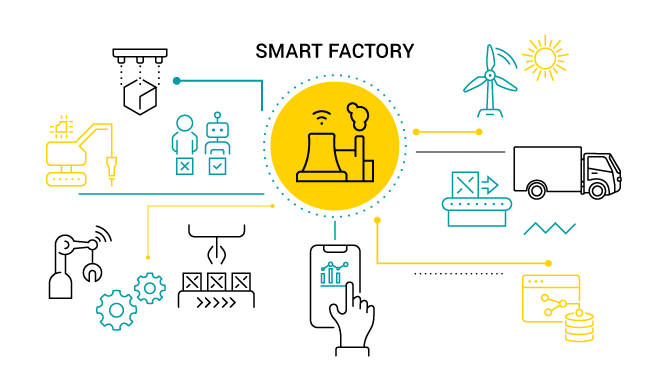

## What "Smart Factory" Actually Means

Forget the buzzwords. A smart factory simply means: Your factory generates data, you analyze that data, you make better decisions faster, and machines and systems work together intelligently.

That's it. Everything else is details.

## Start Here: Visibility

Most factories are blind. Step one: Make your factory visible. Connect critical machines first. Within a week at a plastic injection molding company, they discovered machines were idle 35% of available time.

Armed with this data, they optimized material delivery and batching. Result? 18% capacity improvement without buying any new machines.

## Phase 2: Integration

Once you have visibility, connect the dots with a Manufacturing Execution System (MES). We implemented a simple MES at a components manufacturer: ₹8 lakhs investment, 4 weeks implementation, immediate benefits in traceability and WIP tracking.

## Phase 3: Analytics and Predictive Maintenance

Monitor machine health indicators (vibration, temperature, power consumption). At an automotive components plant, sensors (₹45,000) detected abnormal vibration patterns. Replaced bearings during planned downtime (₹8,000). Prevented breakdown that would have cost ₹15 lakhs.

## The Bottom Line

Start small. Prove value. Scale systematically. Your competitors are already starting their journey.

The question isn't whether to start. It's whether you can afford not to.

---

**Ready to start your smart factory transformation?**

→ [Smart Factory Solutions](/services/smart-factory-solutions) - Industry 4.0 implementation for SMEs

→ [Business Health Check](/services/business-health-check-strategy) - Assess your digital maturity

→ [Read: 5 Warning Signs You Need a Health Check](/blog/5-signs-business-health-check-needed) - Are you ready to transform?

Frequently Asked Questions

Find answers to common questions about smart manufacturing

Still have questions?

Get in Touch with Our ExpertsTags:

Smart FactoryIoTAutomationSME

Share:

Ready to Implement These Strategies?

Let's discuss how we can help you apply these insights to transform your manufacturing operations.

Get Expert Consultation