Back to Blog

Quality Management

Quality Control Best Practices for Export-Oriented Manufacturers

T. PrabhuSeptember 8, 20257 min

Essential quality control strategies for manufacturers targeting international markets, including compliance requirements and quality management systems.

# The Harsh Truth About Export Quality

I've seen it happen too many times. A manufacturer lands a big export order, celebrates for a week, then the customer rejects the first shipment. Hundreds of thousands down the drain. Relationship destroyed.

The problem? They treated export quality like domestic quality. Big mistake.

International customers don't just want good quality—they demand consistency, documentation, and accountability. No second chances.

## Why Export Quality is Different

When you supply domestically, you can often fix problems quickly. Customer calls, you visit next day, sort it out.

Export? By the time the customer discovers the problem, the goods have traveled thousands of kilometers. You can't just pop over to fix things.

Plus, international customers expect:

- Zero defect tolerance (not "acceptable quality levels")

- Complete traceability (every component, every process)

- Certified compliance (not verbal assurances)

- Documented evidence (not trust-based relationships)

## The Foundation: Quality at Source

The best quality control happens before inspection—not during it.

### Mistake-Proofing (Poka-Yoke)

At a precision engineering company, we were seeing occasional dimension errors. The operator would forget to check a critical measurement.

Solution? We installed a simple limit switch. The machine physically couldn't move forward unless the measurement was within tolerance.

Defects dropped to zero. No willpower required. No dependence on operator memory. Physics prevented mistakes.

That's poka-yoke: Make it impossible to create defects.

Examples we've implemented:

- Color-coded fixtures (wrong part won't fit)

- Automatic counters (can't overfill/underfill)

- Limit switches (machine won't run if setup is wrong)

- Guide pins (parts can only be loaded one way)

### Standard Operating Procedures (SOPs)

Every critical process needs a documented SOP. Not 50-page manuals—simple, visual work instructions.

What makes a good SOP:

- Visual aids (photos, diagrams)

- Critical to quality points highlighted

- Inspection criteria with examples of good/bad

- Available at the point of use (not in a filing cabinet)

At a food processing company, we replaced text-heavy SOPs with visual one-pagers. Training time for new operators dropped by 60%. Quality improved because operators could actually use the documents.

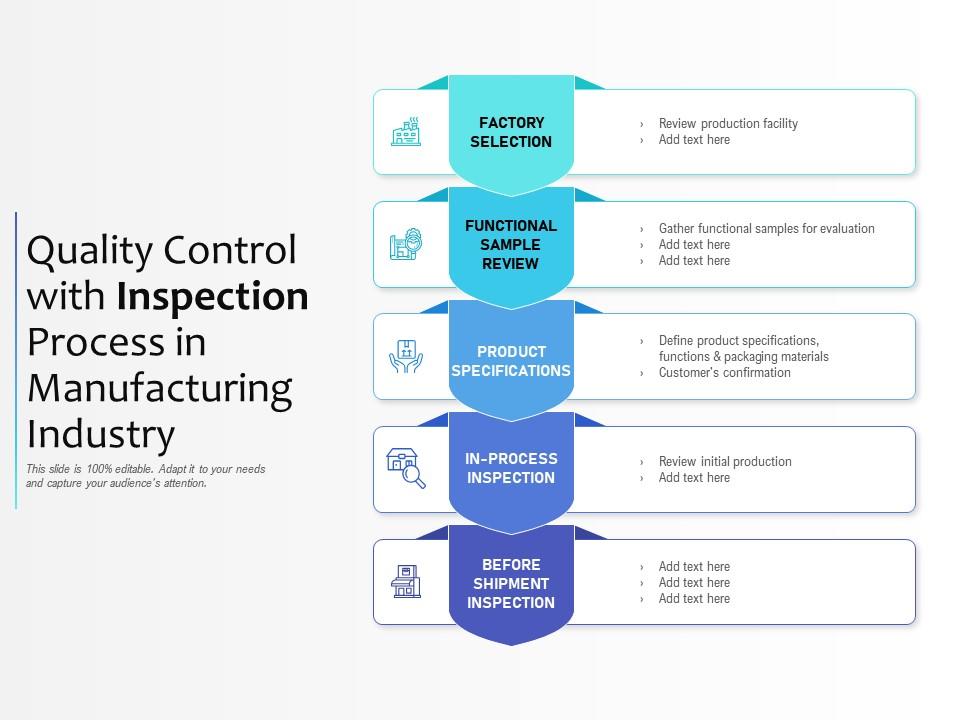

## The Inspection Strategy

You can't inspect quality into a product—but you do need strategic inspection.

### Incoming Material Inspection

Your supplier's problem becomes your problem if you don't catch it early.

Minimum inspection protocol:

- 100% visual inspection (damage, labeling, packaging)

- Sample-based dimensional/functional inspection

- Batch-level testing (critical parameters)

- Documentation verification (certificates, test reports)

One automotive component manufacturer was facing recurring quality issues. Root cause? They were accepting materials without proper inspection. When we implemented incoming inspection, they discovered 15% of material batches had issues.

Catching these early saved millions in rework and customer complaints.

### In-Process Inspection

Don't wait until final inspection to discover problems.

Key checkpoints:

- First-piece inspection (before production run)

- Last-piece inspection (before changeover)

- Process validation (critical parameters in control)

- Operator self-inspection (empowerment, not policing)

### Final Inspection

This is your last defense. Make it count.

100% inspection for critical features

Statistical sampling for non-critical features (use AQL standards)

Functional testing (does it actually work?)

Packaging inspection (export packaging is critical)

### Pre-shipment Inspection

Before anything leaves your factory for export:

- Random sample verification (catch systemic issues)

- Documentation check (everything correct and complete?)

- Packaging verification (suitable for international transport?)

- Quantity verification (matches order and documents?)

## Documentation: Your Best Defense

When things go wrong (and sometimes they will), documentation is your lifeline.

### Essential Records:

Batch Records:

- Raw material lot numbers used

- Process parameters recorded

- Operators involved

- Inspection results

- Any deviations and actions taken

Inspection Records:

- What was inspected

- When and by whom

- Results with measurements

- Accept/reject decisions

- Photos of any issues

Test Certificates:

- Material test certificates

- In-house test reports

- Third-party test results

- Calibration certificates

Traceability:

Every finished product should be traceable back to:

- Raw material batches

- Process parameters

- Operators and machines

- Inspection results

I've seen manufacturers save million-dollar customer relationships because they could prove exactly what happened and where.

## Statistical Process Control (SPC)

SPC sounds complex, but the concept is simple: monitor your process to catch problems before they create defects.

Instead of just measuring the product (lagging indicator), measure the process (leading indicator).

Example: At a plastic injection molding company, we implemented SPC on key parameters like temperature, pressure, and cycle time. When we saw these parameters drifting, we adjusted before producing defects.

Result? Defect rate dropped from 2.3% to 0.4%.

Start simple:

- Pick 3-5 critical process parameters

- Chart them (simple control charts)

- Define control limits

- Investigate when parameters drift

- Adjust processes, not just products

## Calibration: The Forgotten Critical

Your measurements are only as good as your instruments.

Calibration requirements:

- Frequency: Define based on usage and criticality

- Standards: Use traceable, certified standards

- Documentation: Certificate of calibration

- Labeling: Clear status labels (calibrated, due, out of tolerance)

- Quarantine: Non-calibrated instruments cannot be used

We've seen factories where instruments hadn't been calibrated in 3 years. They were measuring products with rulers that were 2mm off. All their quality data was worthless.

## Training: Invest in Your People

The best quality system fails if operators aren't properly trained.

Effective training includes:

- Technical skills (how to perform the operation)

- Quality awareness (why quality matters)

- Inspection techniques (how to identify defects)

- Problem-solving (what to do when issues arise)

- Documentation (how to record properly)

At a textile manufacturer, we implemented comprehensive operator training. Within 3 months, operators were catching 80% of potential quality issues themselves—before inspection.

## Supplier Quality Management

Your quality is only as good as your suppliers'.

Supplier selection criteria:

- Quality management system certification

- Process capabilities

- Quality track record

- Inspection capabilities

- Willingness to be audited

Ongoing supplier management:

- Regular performance reviews

- Supplier audits

- Collaborative improvement

- Clear specifications and expectations

- Escalation procedures for issues

## Certifications and Compliance

For export markets, certifications aren't optional—they're entry tickets.

Common requirements:

- ISO 9001 (Quality Management System) - Almost universal

- ISO 14001 (Environmental) - Increasingly common

- IATF 16949 (Automotive)

- ISO 13485 (Medical Devices)

- FSSC 22000 (Food Safety)

- Customer-specific requirements

Certification isn't just paperwork—it forces you to build proper systems.

## Corrective and Preventive Action (CAPA)

When problems occur, don't just fix the symptom—fix the root cause.

Effective CAPA process:

1. Problem identification (what went wrong?)

2. Containment (prevent more bad product)

3. Root cause analysis (why did it happen?)

- Use 5 Whys, Fishbone, etc.

4. Corrective action (fix the root cause)

5. Preventive action (prevent recurrence)

6. Verification (did it work?)

7. Standardization (make it permanent)

One automotive supplier we worked with was averaging 15 customer complaints per month. After implementing proper CAPA, complaints dropped to 2 per month within 6 months.

The difference? They stopped firefighting and started fixing root causes.

## Customer Communication

When issues arise (and they will), communication makes all the difference.

Best practices:

- Immediate notification (don't wait for customer to discover)

- Honest assessment (no sugar-coating)

- Action plan (what you'll do about it)

- Timeline (when it will be fixed)

- Updates (keep them informed)

- Root cause (prove you understand the problem)

- Prevention (prove it won't happen again)

I've seen manufacturers maintain strong relationships despite quality issues because they communicated well. And I've seen relationships destroyed not by quality issues, but by poor communication.

## Cost of Quality: The Business Case

Quality isn't free—but poor quality is expensive.

Cost of Good Quality (Investment):

- Prevention costs (training, poka-yoke, process improvement)

- Appraisal costs (inspection, testing, calibration)

Cost of Poor Quality (Waste):

- Internal failure (scrap, rework, downtime)

- External failure (returns, warranty, reputation damage)

Typically, every ₹1 invested in prevention saves ₹10 in failure costs.

## Real Success Story

A precision machining company wanted to break into European exports. Their domestic quality was decent (2% defects), but that wouldn't fly in Europe.

What we did:

Month 1-2: Assessment and gap analysis

- Documented current processes

- Identified quality risks

- Defined improvement priorities

Month 3-4: System building

- Implemented poka-yoke devices

- Created visual work instructions

- Established inspection protocols

- Set up SPC for critical processes

Month 5-6: Training and documentation

- Trained all operators

- Implemented traceability system

- Created quality records

- Prepared for ISO 9001

Month 7-8: Trial runs

- Produced trial batches to export standards

- Third-party validation

- Process refinement

Results:

- Defect rate: Reduced to 0.3%

- ISO 9001 certification: Achieved

- Customer approval: Passed first time

- Export orders: Secured €2M annually

Investment: ₹18 lakhs

Annual benefit: ₹85 lakhs (reduced scrap + new export business)

## Getting Started

If you're serious about export quality:

1. Benchmark against international standards (not domestic competitors)

2. Document everything (assume you'll need to prove it)

3. Invest in prevention (not just inspection)

4. Train your people (they're your quality system)

5. Build traceability (from raw material to customer)

6. Get certified (ISO 9001 minimum)

7. Audit yourself (find gaps before customers do)

## The Bottom Line

Export quality isn't harder than domestic quality—it's just more demanding.

International customers expect:

- Consistency (not just capable, but controlled)

- Evidence (not trust-based assurances)

- System (not individual heroics)

- Professionalism (documentation, communication, accountability)

The manufacturers who succeed in export markets aren't necessarily those with the best technology. They're the ones with the best systems.

Build the system. Train your people. Document everything. Improve continuously.

The export market is waiting. But only for those who are ready.

---

**Ready to build world-class quality systems?**

→ [Lean Manufacturing Excellence](/services/lean-manufacturing-excellence) - Quality at source methodologies

→ [Business Health Check](/services/business-health-check-strategy) - Assess your quality maturity

→ [Read: Top 10 Manufacturing Wastes](/blog/top-10-manufacturing-wastes) - Eliminate defects systematically

Tags:

QualityExportComplianceManufacturing

Share:

Ready to Implement These Strategies?

Let's discuss how we can help you apply these insights to transform your manufacturing operations.

Get Expert Consultation