Back to Blog

Lean Manufacturing

The Complete Guide to Lean Manufacturing for SMEs

Nimish DaveOctober 15, 20258 min

Discover how small and medium enterprises can implement lean manufacturing principles to eliminate waste, improve efficiency, and boost profitability without massive investments.

# Introduction

Let me tell you something I've learned after working with 55+ manufacturers: Lean isn't just for Toyota. In fact, some of our SME clients see results faster than large corporations—precisely because they're nimble.

Last month, I was at a mid-sized auto component manufacturer in Pune. The owner told me, "Nimish, we can't afford expensive consultants or fancy software." Three months later, they'd reduced lead time by 35% and inventory by ₹47 lakhs. Their investment? Mostly time and commitment.

That's what this guide is about—practical lean for real manufacturers.

## What Lean Actually Means (Beyond the Buzzwords)

Lean manufacturing is simple: Create more value for customers using fewer resources. But here's what it really means on your shop floor:

- Stop making things nobody ordered yet (overproduction waste)

- Stop moving materials unnecessarily (transportation waste)

- Stop waiting (time waste)

- Stop hunting for tools (motion waste)

- Stop making defects (quality waste)

- Stop holding excess inventory (capital waste)

I've seen factories where operators walk 8 kilometers per shift just fetching tools and materials. That's not manufacturing—that's a cardio workout.

## The 5S Foundation: Unglamorous But Essential

Every successful lean transformation I've led started with 5S. Not because it's fancy, but because it works.

### Sort (Seiri) - The Red Tag Event

We did this at a textile mill in Surat. Tagged everything with red tags: "Do we need this?" Result? They freed up 40% of their floor space. Turns out they'd been storing broken equipment "just in case" for seven years.

### Set in Order (Seiton) - A Place for Everything

Visual management is key. Shadow boards, color coding, labeled locations. At one factory, we reduced tool search time from 15 minutes to 30 seconds. That's 14.5 minutes per shift × 2 shifts × 300 workers. You do the math.

### Shine (Seiso) - Clean to Inspect

Cleaning isn't about looking pretty—it's about finding problems. When operators clean their machines daily, they spot oil leaks, loose bolts, and wear before catastrophic failure.

### Standardize (Seiketsu) - Make It Stick

Document the best way to do things. One-point lessons. Visual work instructions. I'm not talking about thick manuals nobody reads—I mean simple, visual guides.

### Sustain (Shitsuke) - The Hardest Part

This is where most companies fail. We implement audits, celebrations, and accountability. Make 5S part of daily routine, not a monthly cleanup event.

## Value Stream Mapping: See Your Factory Differently

VSM changed how I see manufacturing. It's like putting on X-ray glasses—suddenly you see all the waste.

Last year, we mapped a process at a precision engineering firm. Total cycle time: 12 days. Value-adding time? 3.2 hours. The rest was waiting, moving, and sitting.

How to Start:

1. Pick one product family

2. Walk the current process physically (don't sit in a conference room)

3. Time everything—processing, waiting, moving

4. Draw the current state honestly

5. Design the future state (eliminate the obvious waste)

6. Implement changes in phases

## Pull Systems: Stop Pushing, Start Pulling

Most factories push production: "Make 1000 units because the forecast says so." Then they sit in inventory, consuming cash.

Pull systems flip this: Make only what the customer ordered, when they ordered it.

A simple kanban system at a furniture manufacturer reduced their finished goods inventory from 45 days to 8 days. They freed up ₹2.3 crores in working capital.

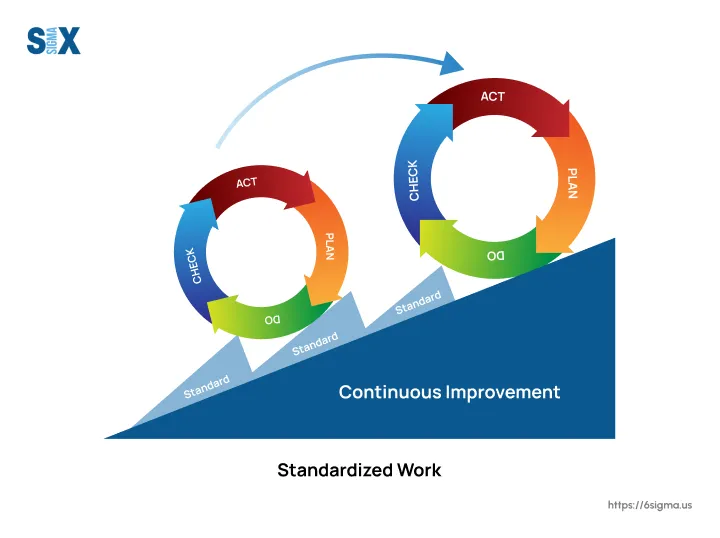

## Standard Work: The Foundation of Improvement

Here's a truth that surprises people: You can't improve what isn't standardized.

I've seen factories where five different operators do the same job five different ways. How do you improve that? You don't know which way is best.

Standard work documents:

- The best-known way to do a task

- The sequence of operations

- The time each step should take

- Work-in-process levels

Then—and this is critical—you improve it. Standard work isn't a prison; it's a baseline for kaizen.

## Quick Wins: Build Momentum

Don't try to transform everything at once. Pick quick wins:

1. Tool organization (5S in tooling area)

2. Visual management (production boards)

3. Line balancing (eliminate obvious bottlenecks)

4. Quick changeover (SMED basics)

Each win builds credibility and momentum.

## The Real Challenges (And What to Do About Them)

### "My employees resist change"

Of course they do. Change is scary. Here's what works:

- Involve them in the solution

- Explain the "why" clearly

- Start voluntary, with enthusiasts

- Celebrate early wins visibly

- Address fears honestly

### "We don't have time for this"

I hear this a lot. My response: "You don't have time NOT to do this." The time you invest in lean gets paid back many times over.

### "Our business is different"

Maybe. But the principles aren't. I've implemented lean in textiles, auto components, pharmaceuticals, food processing, and precision engineering. The tools adapt.

### "We tried lean before. It didn't stick"

Most lean transformations fail not because the tools don't work, but because:

- Leadership wasn't committed

- It was treated as a project, not a journey

- No follow-up or auditing

- People weren't trained properly

Learn from those mistakes.

## Expected Results (Real Numbers)

Based on our 55+ client transformations:

- Productivity: 15-35% improvement

- Quality defects: 40-60% reduction

- Lead time: 30-50% reduction

- Inventory: 20-45% reduction

- Floor space: 20-40% recovered

- Working capital: Freed up 15-25%

These aren't guarantees—every factory is different. But they're typical when lean is implemented seriously.

## Getting Started: The First 90 Days

Weeks 1-2: Assessment & Training

- Leadership lean training

- Current state documentation

- Select pilot area

Weeks 3-6: 5S Implementation

- Red tag event

- Organization

- Visual controls

- Initial audit system

Weeks 7-10: Value Stream Mapping

- Map current state

- Identify waste

- Design future state

- Plan improvements

Weeks 11-12: Quick Improvements

- Implement obvious wins

- Measure results

- Celebrate successes

Day 90: Review & Plan Next Phase

## The Bottom Line

Lean manufacturing works for SMEs. I've seen it transform struggling factories into industry leaders.

But it's not magic. It requires:

- Commitment from the top

- Involvement from the floor

- Patience for cultural change

- Persistence when things get hard

Start small. Build momentum. Keep improving.

And remember: Every manufacturer who's succeeding with lean started exactly where you are now—at the beginning, wondering if it would work for them.

It will. But only if you start.

---

**Ready to start your lean transformation?**

→ [Lean Manufacturing Excellence Services](/services/lean-manufacturing-excellence) - Expert guidance for your journey

→ [Business Health Check](/services/business-health-check-strategy) - Assess your current state and opportunities

→ [Read: Top 10 Manufacturing Wastes](/blog/top-10-manufacturing-wastes) - Identify what's costing you

Frequently Asked Questions

Find answers to common questions about lean manufacturing

Still have questions?

Get in Touch with Our ExpertsTags:

LeanSMEManufacturingProcess Improvement

Share:

Ready to Implement These Strategies?

Let's discuss how we can help you apply these insights to transform your manufacturing operations.

Get Expert Consultation